Soundproof insulation is used in both commercial buildings and homes to help reduce the amount of noise that's transmitted to other parts of the building.

Unless you live in a tropical or sub-tropical climate, insulation plays an important role in your life. It helps mitigate heat transfer by keeping your home warm in the winter and cool in the summer.

Not all sound is the same. There are two different types of sound that can invade your living space: airborne and structure-borne.

Any sound that travels through the air is considered airborne. Examples include birds chirping, dogs barking, conversations, television, and car engines.

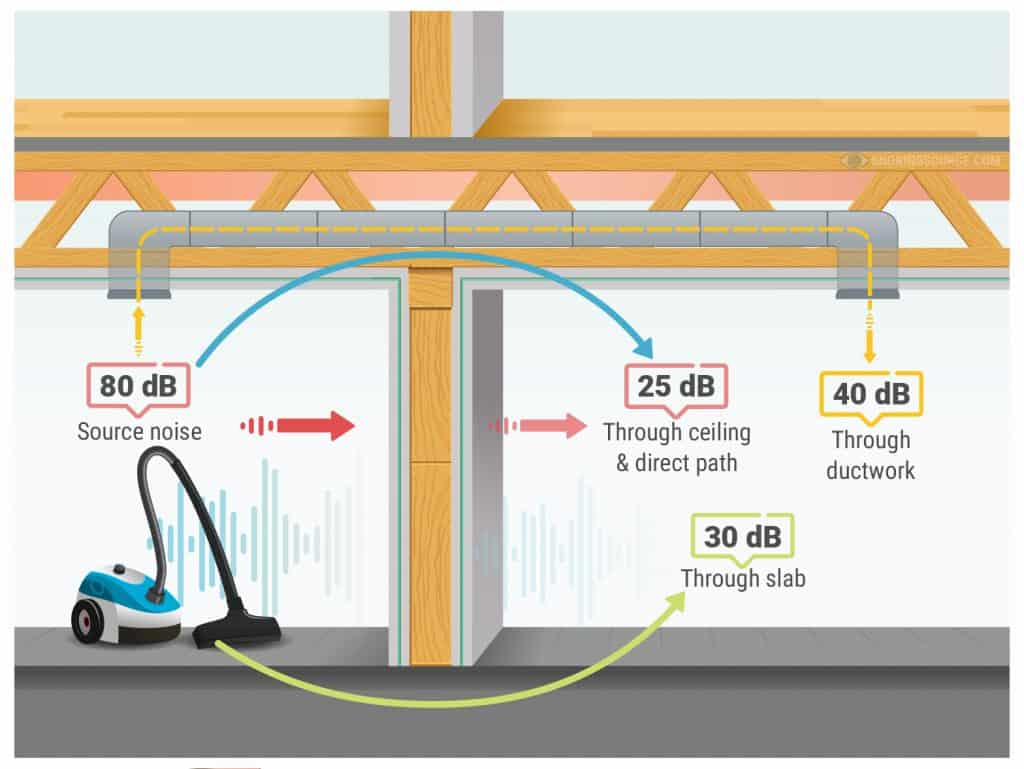

Sound waves will transmit until they collide with a structural element like a wall. The collision causes vibrations that transmit into adjacent spaces.

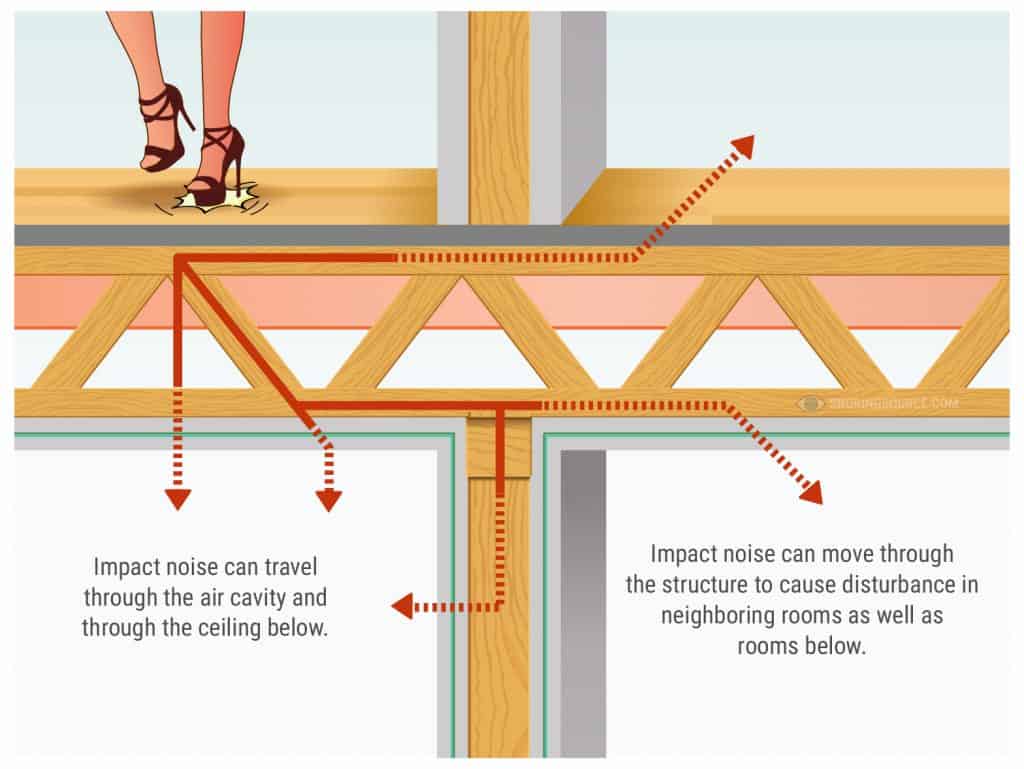

In simple terms, structure-borne noise is created when one solid object impacts another. The sound waves then create vibrations which travel through a building’s structural elements like walls or floors.

There are actually two types of structure-borne noise:

Impact noise is caused by vibrations that are directly transmitted, such as footfalls on the floor right above you with the sound they make passing through the ceiling.

Flanking noise travels a more indirect route, such as moving through air cavities or ductwork in an attic or wall.

Both are at least somewhat controllable with soundproof insulation, but flanking noise is by far the toughest to eliminate.

Some sources of structure-borne noise are easy to identify, such as the footsteps we just mentioned. Others can be very difficult to trace. For example, a basement electrical box can generate low-frequency noise which vibrates through studs or walls, and is only identifiable to human ears as an annoying hum.

Structure-borne noise eventually generates airborne noise. Otherwise, it wouldn't be perceivable. But airborne noise can actually generate structure-borne noise, too.

Think of a truck rumbling by your home. You can hear its engine noise through your windows, which is airborne noise. But the vibrations the engine creates may be transmitted through the ground to shake your home’s foundation and rattle your windows, creating structure-borne noise.

In both cases, unwanted sound can be minimized or eliminated with the use of soundproofing insulation. The types of materials used for each type of noise, however, are very different.

The majority of structure-borne noise is carried through floors and walls. The simplest way to prevent much of it is through the use of soft carpeting and soundproof underlayment which can help absorb airborne noise as well.

Many companies also sell ceiling isolation hangers to be used with drop ceilings, which blunt vibrations and other structure-borne noise transmitted from above. The dense, flexible product known as MLV (mass-loaded vinyl) or soundproof blankets are often used to wrap ductwork and pipes, to lessen the amount of noise they can transmit.

More serious ways of blocking this type of sound, like avoiding air gaps where noise can resonate, should be undertaken during construction, since retrofitting a building can be horrendously expensive.

As for airborne noise, some prevention methods like installing several layers of soundproof drywall, using metal studs (instead of wood ones), or choosing solid-core doors do require either foresight during construction or retrofitting. But that’s not necessary to minimize airborne noise in most every-day cases, and the task can be much easier.

Even small steps can help. For instance, dense décor components like thick furniture upholstery absorb noise quite well. Hanging soundproof curtains or blankets can insulate rooms against lower levels of airborne noise.

There’s an effective middle ground when those simpler measures aren’t enough: the installation of soundproof insulating material.

It’s certainly more complicated and expensive than choosing the right furnishings or hanging some curtains, but soundproofing is much less difficult and less costly than ripping out drywall and rebuilding a room. It can also eliminate most troublesome airborne noise for good.

Absorbing sound: Porous soundproofing material allows the penetration of sound waves. It will convert incident sound energy into heat energy through frictional and viscous resistance in the fibrous or cellular structure of the material.

Damping sound: Materials like rubber and foam “damps” the sound caused by vibrations by absorbing the energy created by sound waves, and turning it into heat which is then harmlessly released.

Two other types of soundproofing won’t normally be provided by simple acoustic insulation:

Blocking sound: Thick, dense soundproofing sheets are usually required to prevent sound waves from entering a space, instead reflecting or deflecting it so it can’t be transmitted through the material.

Decoupling sound: Constructing walls or framing elements so they are separated or staggered can remove the straight path sound needs to travel between rooms.

You’ll often see three different types of ratings for the efficiency of soundproofing materials.

STC (Sound Transmission Class) measures how well a material attenuates airborne sound. The average home has an STC between 20-40 depending on the quality of its construction. Building codes usually require an STC of 50 for floors, walls, and ceilings. The higher the STC rating, the better.

NRC (Noise Reduction Coefficient) and SAA (Sound Absorption Average) each measure how much sound a material will absorb, on a scale of 0.0 to 1.0.

The closer to 1.0, the better. These metrics can also be expressed as the percentage of sound that’s absorbed so the closer to 100%, the better.

That should be enough background information to help you choose the right product for your home or business.

Let’s move on to specifics.

There are three main materials that are used to manufacture acoustic insulation: mineral wool, fiberglass, and cellulose material.

This porous, dense material is made from a mix of substances like stone (usually igneous rock such as basalt or silica).

They’re heated until they’re in liquid form and then spun (much like cotton candy) into a flexible material generally sold as batts, panels or loose-fill insulation. Unlike most soundproofing products, mineral wool is ideal for absorbing and damping both airborne and structure-borne sound, while also reducing vibration and reverberations.

The porous nature of mineral wool allows sound waves to enter easily, but they’re trapped inside the narrow fibrous material so their energy is converted to heat. Mineral wool is sometimes called rock wool, slag wool, or stone wool.

There are two general grades of mineral wool. High-performance products have an NRC ranging from 0.95 to 1.05; multi-purpose products, more often used for applications like filtering or hydroponics, are less expensive but still have an NRC in the 0.8-0.9 range.

Mineral wool is also an excellent choice for thermal insulation.

Less expensive but more difficult to work with (be sure to wear a mask and gloves), fiberglass insulation is made from spun plastic with small, embedded glass fibers.

While its thermal properties don’t match those of mineral wool, it has nearly the same acoustic performance level. That makes it a decent alternative when budget is an issue, although rock wool’s greater density makes it more effective than fiberglass at trapping sound.

Fiberglass has other properties which make it a lesser choice than mineral wool as soundproofing insulation material. Over time fiberglass can become compressed or lose its form, reducing its sound absorption ability.

The same thing can happen to its thermal protection properties, normally quite good but subject to erosion over time. The NRC of fiberglass is directly related to how much is used; one inch of high-quality fiberglass insulation can come in around 0.65-0.7, but double the amount and the NRC increases to 0.95-1.0. Rigid fiberglass panels are best of all for acoustic purposes.

Cotton doesn’t have the same reputation as mineral wool or fiberglass when used as soundproofing insulation, but it’s lighter, and it’s the least-expensive and most environmentally-friendly.

Cotton acoustic insulation is normally sold in panels, making it easy to install, and its compact-able, fluffy fibers make it particularly good at absorbing high-frequency noise and preventing sound reverberation. A top-quality two-inch thick panel can have an NRC as high as 1.0.

Two other types of soundproofing insulation aren’t in the same ballpark when it comes to sound absorption, but they’re very good at blocking or deadening sound.

A common choice for noise deadening, blow-in cellulose is less expensive than spray foam (which we’ll discuss next) and can provide a NRC as high as 0.8.

The material is mostly composed of recycled newsprint so if it’s blown into a space using proper technique, it remains in place without air pockets or voids. It won’t completely absorb sound, but it will definitely deaden it while also minimizing the vibrations it can cause.

This material can also be applied in a packed form which provides a higher-density and more effective insulation. Since the installation requires a blower capable of strong pressure, however, it’s more of a job for a professional than a home DIY’er.

This material, sometimes called SPF (spray polyurethane foam), is a liquid chemical which can expand to more than 50 times its original volume after it’s been sprayed into a space and has cured. It comes in two basic forms, high-density (known as closed-cell foam) and low-density (open-cell foam).

Open-cell spray foam is the better choice to deaden noise, not because it’s a better performer initially; it’s not. Denser, closed-cell foam becomes harder after it’s cured, so it often pulls away from the structure it’s filling and leaves holes through which sound can pass.

Open-cell foam, on the other hand, fills all of the open spots and then stays there. So even though it’s not as dense, it blocks sound better for long periods of time, with an average NRC as high as 0.7.

Spray foam also helps to reduce structure-borne noise. Be aware though, it’s pretty expensive.

Many of these products are available in multiple sizes or forms. For example, fiberglass insulation can be purchased in several different thicknesses, and mineral wool is sold in batts, loose fill and solid panels.

For that reason, this list is not exhaustive; its best use is as a guide to high-quality manufacturers, and then matching the company’s products to your specific needs and budget.

When considering alternatives, remember that thicker insulation will usually do a better job of absorbing or blocking low frequencies.

This is the flexible form of mineral wool, made by one of the premier manufacturers in the industry. Its primary use is placement inside drywall and ceilings, but it can also be used to wrap ducts and pipes.

The density of this mineral wool is 2.5 pounds per cubic foot, which isn’t the best density you can find. However, it absorbs about the same amount of sound as denser mineral wool batts, at a much lower price.

Its best performance is in damping high- and mid-range frequencies, when it delivers a NRC greater than 1.0. As you can guess from the product’s name, it’s also heat resistant (up to 2150°), and does a very good job of thermal insulation.

This is a mineral wool in the form of 2’x4’ rigid boards, two inches thick with a density of eight pounds per cubic foot. The panels can be placed behind walls or above ceilings, and while it’s a bit of a chore to cut the panels into smaller sizes, it can be done with a sharp tool.

As with the company’s batts, the best sound absorption performance is with high- and mid-range frequencies, but it can damp some bass reverberations as well.

Because of the panels’ rigid form, they can also be covered with material and used inside a room as acoustic panels to absorb airborne noise and echoes. The NRC rating of this Rockboard is right around 0.9, and like the Roxul batts, it can withstand enormous heat while being resistant to mold and water.

The industry standard, this Owens Corning faced fiberglass comes in 2’x4’ sheets that are two inches thick, with a density of three pounds per cubic foot and an NRC of 1.0. (The one-inch thick sheets have an NRC of 0.7.)

This insulation is mold-and-heat resistant, lightweight and easy to work with as long as you’re careful (wear gloves and goggles!). But it’s expensive, so don’t buy more than you need.

For best practice, you should cover the sheets with acoustic fabric since that will hold in the fiberglass fibers while providing additional sound absorption. Owens Corning also makes terrific rolls of unfaced fiberglass insulation that’s great for stuffing into small areas and crevices.

This product is almost identical to the Owens Corning 703 fiberglass, but sold at a lower price. The only major difference (other than its price) is that the ATS Acoustics insulation is more easily compressed, so it’s a bit easier to fit into tight spaces.

Eco-friendly and relatively inexpensive, these 2’x4’ two-inch thick cotton batts are most commonly wrapped in fabric and used as acoustic panels. They can also easily be used to improve sound absorption and damping inside walls and ceilings, as long as fire-resistance isn’t an issue.

Since they’re so flexible, they’re best utilized when placed inside a solid frame but can also be effective soundproofing insulation when stuffed into smaller areas. At most frequencies, the NRC of the ATS cotton batts is right around 1.05, and it has a density of five pounds per cubic foot.

We like this product because it’s formulated to produce very little dust – which can be a huge problem when installing blown-in cellulose. It provides good noise deadening, particularly for low frequency structure-borne sound, and it’s also very good for thermal protection against heat and cold, while meeting Class 1 fire standards.

NRC ratings usually aren’t provided for blown cellulose (or spray foam) products, but when used for the right purposes – that is, if you don’t count on it to significantly lower airborne noise – it does a great job.

As previously explained, open-cell spray foam is a low-density product, but it’s better than closed-cell foam for long-term noise deadening. That’s because it holds its form after expanding and curing, and doesn’t contract to leave open pathways for noise.

The Foam It Green foam is fire-retardant, mold-resistant and anti-microbial, but be aware that it’s not moisture-resistant, so it shouldn’t be used in areas that don’t stay completely dry.

Also be aware that spray foam begins curing as soon as it’s applied – so be sure you have a plan before you pull out the sprayer and start shooting this foam into your home’s open spaces.

Snoringsource.com is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for website owners to earn advertising fees by advertising and linking to amazon(.com, .co.uk, .ca etc) and any other website that may be affiliated with Amazon Service LLC Associates Program.