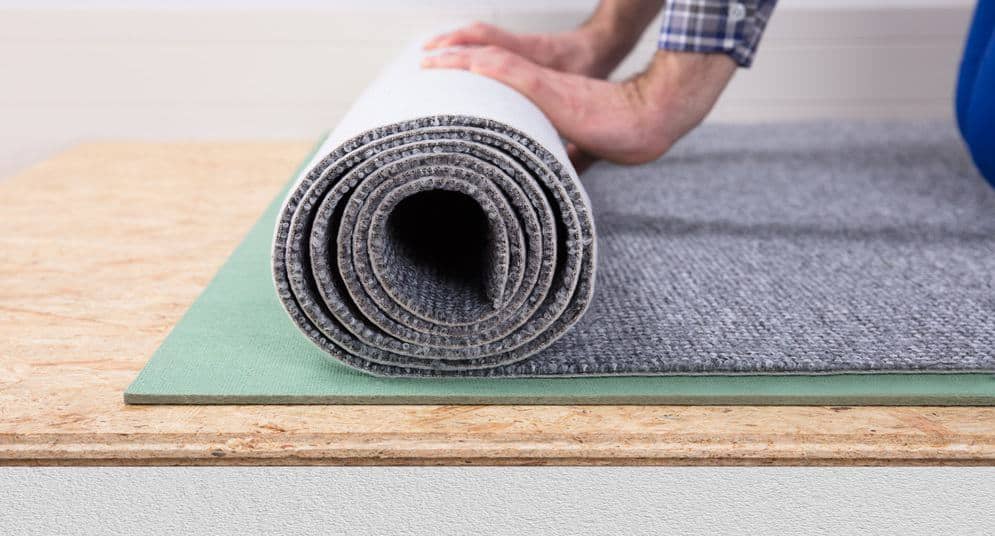

If you’ve ever bought carpeting or hardwood flooring, you know that you also need underlayment. That’s the usually-thin layer of material which is placed between the subfloor and the new carpet or floor. (It’s often needed for most other types of flooring as well.)

The underlayment establishes a flat, stable base for the flooring. It provides extra comfort for those walking on carpet, acts as a firm surface that tile can adhere to, functions as a moisture barrier if needed – and can also deaden or absorb some of the sound and reverberation caused when people walk on the floor.

All types of underlayment, whether they’re plywood, foam, cork or another material, will somewhat deaden unwanted noise. However, underlayment specifically engineered for soundproofing floors can help to prevent structure-borne noise and eliminate footfalls.

We've mentioned that different types of underlayment are appropriate for different types of flooring – while this is guide is structured as a list, your choice will be narrrowed down based on your type of flooring.

This Roberts felt underlayment is primarily intended for use with either laminate or engineered wood floors, so you may want to move on if your floor is hardwood.

The sound absorption and reduction metrics of the Roberts felt are strong, with a STC rating of 66 and an IIC rating of 67. To put that into perspective, the International Building Code requires each rating to be at least 50, and many state, municipal or HOA codes require STC and IIC to be at least 60 for multi-unit buildings. Generally speaking, 60 is considered to be “superior” soundproofing, and 70 is considered “virtually soundproof.”

The Roberts felt underlayment comes in a 360-square foot roll and is priced fairly. It is dense, 4mm thick and made from recycled felt, and an attached plastic film provides decent vapor barrier protection.

As we prefaced at the top, this product is designed for use with engineered and laminate wood floors, not nailed floorboards.

Overview of Specifications:

While this felt underlayment isn’t quite as dense as the Roberts felt we just looked at, it has slightly higher noise-reducing properties and can be used on virtually all types of wood floors, including nailed-down hardwood and vinyl plank flooring that’s at least 5mm thick. Its STC rating is 66 and the IIC rating is a stellar 71, meaning nearly all noise that’s “blockable” will indeed be blocked by QuietWalk Plus.

It has several other attractive features as well. The recycled fibers allow the felt to breathe and there’s an attached vapor barrier; the underlayment is Greenguard certified to release no VOCs or harmful gases; it’s approved for use with radiant heating systems that are installed in the floor; and it’s exceptionally easy to install. The 100-foot rolls are more expensive (per square foot) than the Roberts product, but this product is worth its extra price.

Overview of Specifications:

Here’s our budget choice, suitable for use with engineered floating wood floors and with wood laminate flooring. The Feather Step underlayment is made from dense foam that’s 2mm thick and more rugged than many of its foam competitors, and it provides noise reduction measured at STC 65 and IIC 64. While it won’t make a room quite as “soundproof” as the QuietWalk underlayment, it will still make a big difference in noise comfort.

There is an attached film that serves as a vapor barrier, and the Feather Step product comes in 100-foot rolls which are very attractively-priced. Just be warned: if you use this with vinyl plank or hardwood flooring, it could void your warranty.

Overview of Specifications:

This isn’t actually soundproof underlayment, but it can be used for that purpose. It’s a flexible product known as mass loaded vinyl (MLV) which is commonly used as a sound barrier in a variety of ways: hung between rooms, wrapped around pipes and ducts to prevent noise transmission, used to screen off noisy industrial equipment from the rest of a plant, or installed in the passenger areas of vehicles to reduce engine vibration. In all of those cases, its primary function is to deaden sound.

However, MLV can also be attached to drywall or laid underneath flooring – which is the use we’re most interested in. The TMS blanket is a thin (1/8”) layer of extruded virgin vinyl which is both dense and very heavy, and can be spread below nearly any type of floor.

Its STC is only 27 so it won’t do the job all by itself, but it’s so thin that you can install several layers and dramatically boost its sound absorbing properties. This MLV product may not be our first choice as a soundproof underlayment, but it’s a good multi-purpose option.

Overview of Specifications:

We finish where we started, with a Roberts product. It’s more expensive than the company’s felt underlayment, but it provides one important benefit for that extra cost: it’s made from foam with a layer of cushioning foam beads between the layers.

That extra layer helps a bit with comfort and noise reduction, but the beads are there for a different reason. They allow air to circulate throughout the underlayment, preventing the growth of mold while also acting as a vapor barrier. That means this the perfect product to use for floor-level (or lower) applications in humid or moisture-prone climates and locations.

This foam is quite impressive, maintaining almost all of its thickness after regular use. By comparison, most foam underlays will eventually compress to nearly half their original thickness. It works for noise absorption and damping as well, with an STC rating of 66 and an IIC rating of 68. As with the Roberts felt, however, their First Step foam is only suitable for laminate or engineered wood floors.

Overview of Specifications:

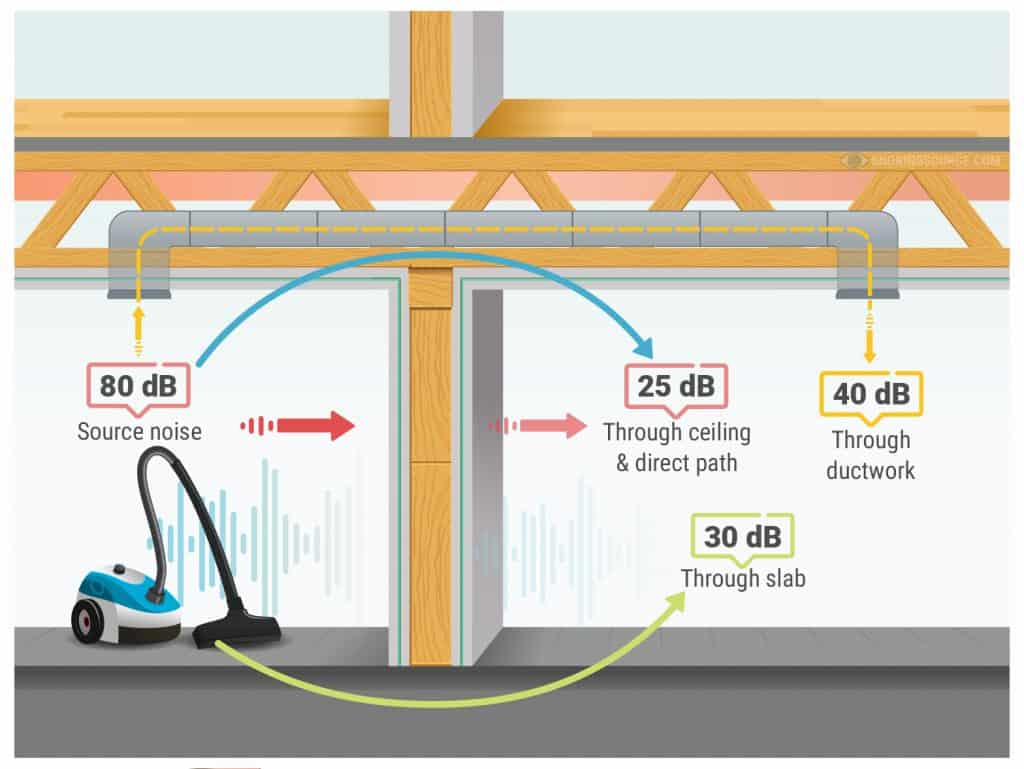

Floors are a common source of noise pollution. Footfalls, people talking, an object falling will all create vibrational energy in the form of sound-waves.

It's important to understand that there are two types of noise involved in soundproofing: airborne and structure-borne.

As the name implies, airborne sound refers to any noise that travels through the air. Examples of airborne noise include conversations, the television, or noise generated by appliances.

The soundwaves generated will travel through the air until they collide with another solid object. This soundwaves then travel through the object and into adjoining spaces.

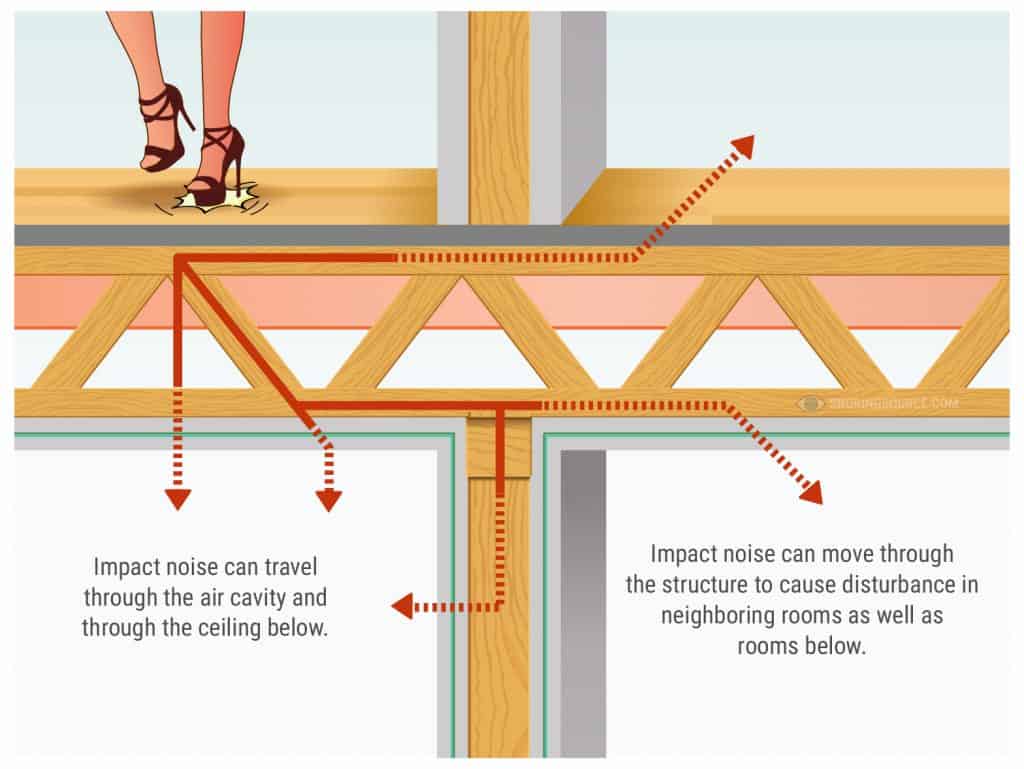

Structure-borne noise is also referred to as impact noise. As the descriptor suggests, soundwaves are generated as a result of an object impacting another object or structure.

For instance footfalls, or a ball impacting the floor or a wall. This impact results in soundwaves being transmitted through a structure and into an adjoining space.

The ideal soundproof underlayment will block both types of sound.

Underlayment products are available in a number of materials. The most common are rubber, vinyl, felt, cork and foam; they’re all quite dense, so they’re ideal for absorbing the maximum amount of airborne noise and deadening structure-borne noise. However, some are better than others for different types of flooring.

Foam and rubber are the best choices, because they’ll make the floor softer to walk on and absorb much of the structure-borne sound that’s created.

Cork is the underlayment that’s most likely to stay firm without flexing, while still deadening sound. Foam is a decent second choice as long as it’s thick and very dense, although cork will last longer and perform better.

Foam works best underneath laminate floors if it has vapor barrier properties, since that type of flooring is particularly susceptible to moisture. Otherwise, cork will provide even more noise reduction.

There’s an important issue to look into before buying underlayment for vinyl flooring: many manufacturers won’t honor warranties if additional underlayment is used.

The good news is that vinyl floor products often ship with attached cork underlayment. If you need (and are allowed to use) additional soundproofing, felt, cork and foam will all work but cork is best because it won’t harm or stain the flooring. Stay away from rubber as it will cause stains.

Most materials aren’t suitable for use under tile floors; a thick subfloor, or a rubber-cork underlayment, is the best approach.

You can buy soundproof underlayment products made from almost all of those materials. Once you decide on the right type for your floor, the next step is to evaluate the sound absorption and deadening properties of the various products you have to choose from.

The flooring industry uses two widely-accepted measurements to test and label its products, including underlayment: Sound Transmission Class and Impact Insulation Class.

A material’s ability to reduce airborne noise is measured by its “Sound Transmission Class,” or STC. It’s determined through a series of complicated lab tests and reported as a number that’s generally between 15 and 80; the higher, the better.

The STC is not calculated on arithmetic or geometric scales, but on a logarithmic one. That means that relatively small differences in STC ratings can mean big differences in sound blocking. The average wood floor has an STC in the neighborhood of 40.

The Impact Insulation Class rating, or IIC, measures how well a material blocks structure-borne noise that’s caused by one object impacting another.

It’s determined in labs after generating somewhat low-tech noise: steel hammers tap the material, with the resulting vibrations measured on a numeric scale similar to the one used for STC.

A non-insulated wood floor would average an ICC of between 40 and 45; most building codes require an IIC of at least 50.

It’s important to understand that even a high-quality soundproof underlayment with high STC and IIC ratings may not completely deaden all sound. Low-frequency noise (the rumbling of a passing truck, the hum of an air conditioner or even superior bass in a home theater setup) is extremely difficult to attenuate – and it’s just as difficult to measure the effectiveness of a material to deaden low-frequency sounds in lab tests.

Nevertheless, installing underlayment products with strong IIC and STC ratings, along with the concurrent use of other soundproofing products like noiseproofing compound and floor joist isolators, will greatly reduce the amount of airborne and structure-borne noise transmitted through your home.

In most cases, the thickness and density of underlayment will go hand-in-hand with its sound reduction ratings. However, if you have a choice, thicker and denser – as you would probably expect – is more effective.

Many underlayments have a built-in vapor barrier (sometimes referred to as “damp proofing”), which is designed to resist moisture and condensation in the area under the flooring. This may not be necessary for upper-story floors, since they’re not normally at risk for the development of unwanted moisture. A vapor barrier is highly desirable, though, for underlayment that’s installed at or below ground level.

It can be tempting to simply install the “free” underlayment that’s included with the purchase of flooring for your home. There’s nothing wrong with using that thin underlayment if you don’t have major problems with noise and its associated vibrations, because it will block some noise and make the floor more comfortable to walk on.

Using an underlayment creates a predictable, smooth surface for flooring installation. In any situation where noise is an issue, however, spending extra for soundproofing underlayment with high STC and IIC ratings is well worth the expense.

Snoringsource.com is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for website owners to earn advertising fees by advertising and linking to amazon(.com, .co.uk, .ca etc) and any other website that may be affiliated with Amazon Service LLC Associates Program.